INTERNATIONAL PAPER (IP) – SPRINGFIELD MILL

Cleaner Air Oregon ProfileEmerald Forest Products, Inc. Plant #1

As part of the Cleaner Air Oregon process, each facility has a dedicated web page to provide communities access to facility information and updates on where it is involved in the process.

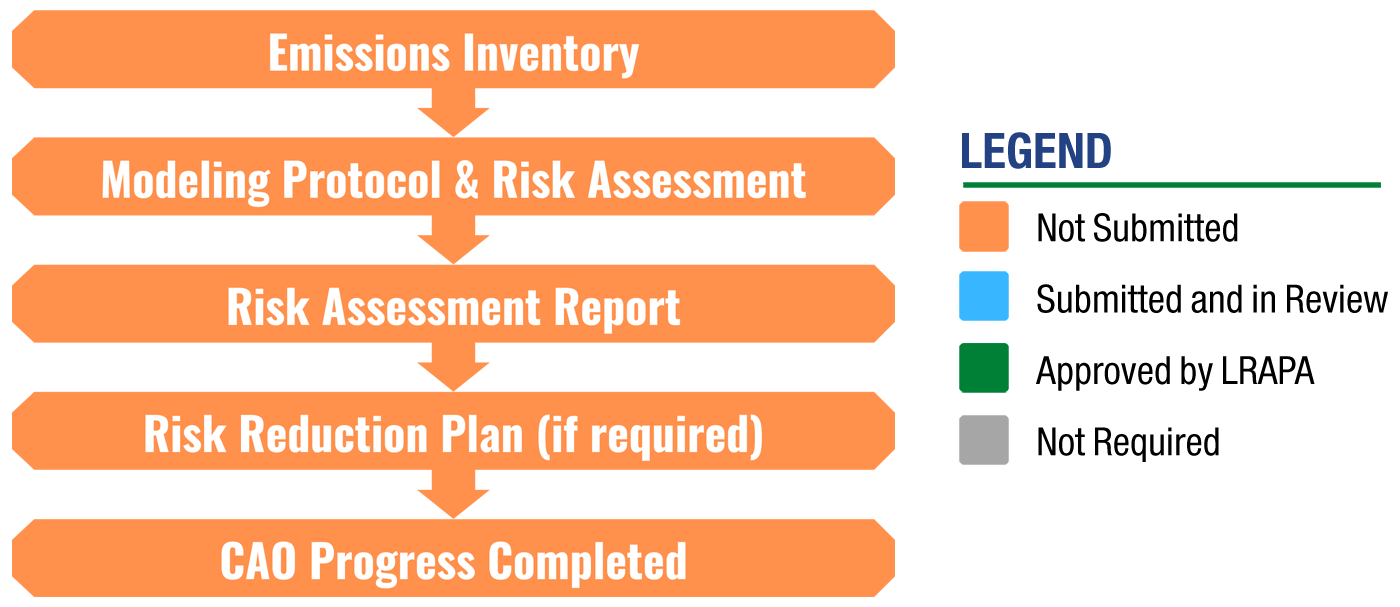

- Each step of the CAO risk assessment process has a section that includes LRAPA’s communications and deliverables from the facility.

- A color-coded graphic shows where a facility is in the Cleaner Air Oregon Process.

- For additional information and history of the program, visit the DEQ Cleaner Air Oregon website.

| Document Type | Anticipated Submittal Date | Approval Date |

|---|---|---|

| Emissions Inventory | TBD | TBD |

| Modeling Protocol | TBD | TBD |

| Risk Assessment Report | TBD | TBD |

| Risk Reduction Plan | TBD - if needed | TBD - if needed |

| CAO Completed | TBD | TBD |

Emissions Inventory

For an introduction to emissions inventories and why they matter, please see EPA’s Fact Sheet. A facility-specific emissions inventory timeline and associated documents are linked below.

Modeling Protocol & Risk Assessment

Risk Assessment Report

This section will be updated when the facility submits a risk assessment report presenting the results of modeling and calculating health risks from the facility. The risk assessment report undergoes public review.

Risk Reduction Plan

CAO Progress Completed

FACILITY

The International Paper Springfield Mill manufactures linerboard which is sold to produce corrugated boxes and packaging containers. Linerboard manufactured at the facility is produced primarily from wood chips and recycled old, corrugated containers (OCC). The facility uses the Kraft pulping process to convert wood chips into unbleached virgin pulp. The facility also operates a 4-turbine electrical cogeneration power plant which supplies steam for pulp and linerboard production and produces electric power for sale. The facility is located at 801 42nd Street in east Springfield and has produced unbleached paper products since it began operating in 1949. The facility was owned and operated by Weyerhaeuser until 2008, when it was sold to International Paper. Learn more about LRAPA’s regulation of International Paper Company, Springfield Mill by viewing their current air permit documents.

Site Address

801 N 42nd St.

Springfield, OR 97478

Current Air Permit

Permit type: Standard ACPD

Source Number: 208850

LRAPA Contact

Max Hueftle

541-736-1056, ext. 231

Site Address

Eugene, Oregon, 97402

Current Air Permit

Source Number: 202528

LRAPA Contact

541-736-1056, ext. 231

Legend

Facility

Emissions Inventory

December 15, 2021: LRAPA calls Emerald Forest Products, Inc. #1 into the program

- LRAPA’s call in letter to EFP#1.

March 4, 2022: Emerald Forest Products, Inc. #1 requests an extension to submit their CAO Emission Inventory.

- EFP#1’s extension request letter.

March 7, 2022: LRAPA approves EFP#1 Emission Inventory extension request with a new deadline of April 15, 2022.

- LRAPA’s extension request approval letter.

April 15, 2022: EFP#1 submits their CAO Emission Inventory by the deadline of April 15,2022.

- EFP#1’s CAO Emission Inventory.

Modeling Protocol & Risk Assessment

Risk Assessment Report

Emerald Forest Products, Inc. Plant #1 is currently in the Emissions Inventory Step of the Cleaner Air Oregon process. This field will be updated once the facility reaches the Modeling Protocol & Risk Assessment portion of CAO.